Product Category

Contact Us

- E-mail: rolly@enamould.com

- Tel: +86-576-81108366

- Skype: enamould

- QQ: 254729571

Product Detail

Product Description

|

1 |

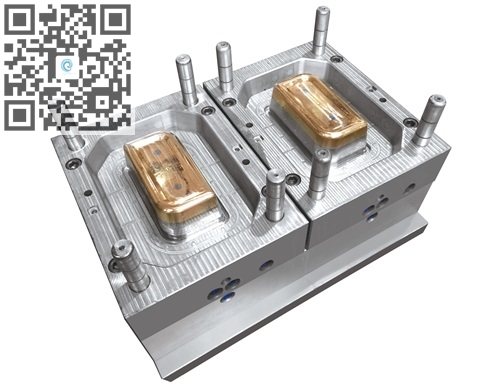

Thin Wall Bucket Mould standard |

HASCO,DME,MEUSBURGER,JIS,CHINA LKM STANDARD |

|

2 |

Thin Wall Bucket Mould base |

LKM/HASCO/DME standard (A,B plate 1730,2311,2312,P20 ) |

|

3 |

Material main core and cavity insert |

P20,DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

4 |

Hardness of steel |

48~58HRC |

|

5 |

Material for Slider ,Lifter and all sub insert use |

1.2767 HRC |

|

6 |

Cavity |

Single-cavity ,Multi-cavity |

|

7 |

A surface request |

EDM & High Polish |

|

8 |

Gate of plastic mould |

Cold runner,Yudo/DME/HASCO/Synventive Hot runner |

|

9 |

Cycle Time |

8sec. |

|

10 |

Mould life time |

More Than 1,000,000 shots |

|

11 |

Quality |

ISO9001-2008 certification |

|

12 |

Product material |

PP,HDPE |

|

13 |

Lead time |

8 Weeks |

|

14 |

Package |

Wooden/Plywood case for tool ,PE bags add export carton for parts |

|

15 |

Payment terms |

T/T |

|

16 |

Trade terms |

FOB NINGBO / SHANGHAI |

|

17 |

Export country |

JORDAN/EGYPT/TURKEY/BRASIL ETC |

|

18 |

Value-added service |

Polish,texture,painting |

|

19 |

As a professional Plastic Injection mould ,Die casting Mould & Molding manufacturer, our range products are covered from Household, Industrial, Auto parts etc. |

|

|

20 |

Clients project's 3D drawings or samples are highly appreciated |

|

Workshop ( Assemble and Machining)

Our Services

1. With strict Quality Management system, make sure you make produce 500,000 to 1,000,000 shots ,with long life.

2. With a perfect mold design and mold making standard criteria.

3. Familiar with HASCO / MISUMI / Jinhong standard parts, specializes in designing HASCO / musumi / Jinhong standard export mode.

4, With all the equipment needed for precision molds, Sodick wire walking, High-speed CNC(Exeron), EDM (Exeron) , surface grinders, milling machines, projectors (Mitutoyo) , 2.5 million testing equipment(Mitutoyo), high-speed injection molding machine(JSW).

5. Machining precision:EDM Precision 0.001mm,Wire EDM Precision 0.001mm,CNC Precision 0.002mm,Grinding Machine Precision 0.001mm.

6. About 30-45 days after getting final confirmation.

7. Provide perfect service ,you can chat or call me within 24hours ,we will react at first time.

About ENA Mould

ENA Mould have nearly 30 years of experience in plastic injection molding processing and mould processing.

ENA Mould focus on manufacturing and designing of solar product, electronic appliance, plastic products,

kitchen utensils and etc.

ENA Mould engineering center is specialized in plastic casting mould and plastic injection mould.

We utilize and invest in new technology and have a highly skilled mould developing and designing team.

1) We can supply good quality plastic injection moulds for making all kinds of plastic items according to your requirements.

2) We own working machines and various advanced mold tooling equipment. We also have established a CAD / CAM / CAE mold design and development center.

3) Our quality, price, after sale services are really competitive

FAQ

1.Q: Are you a factory or trading company?

A: We are factory.

2.Q:Where is your factory located? How can I visit there?

A: Our factory is located in Taizhou city,China. Have both airport and train station.

3.Q:What is your payment?

A:T/T,L/C, Western Union,MoneyGram,Paypal

4.Q: What is your delivery time?

A:45-50 days.